Closed-cell spray foam offers a higher R-value per inch and acts as a vapor barrier, making it generally more energy-efficient in extreme climates and moisture-prone areas. Open-cell spray foam expands more to fill irregular cavities and provides better sound dampening, but it has a lower R-value and allows moisture to pass through. The choice between them depends on the specific climate, the project budget, and whether the primary goal is air sealing, thermal resistance, or moisture control.

Selecting the proper insulation requires understanding how these materials perform in real-world conditions. This breakdown examines the functional differences, cost implications, and specific use cases for each type to help determine the best fit for a property.

Understanding the Two Types

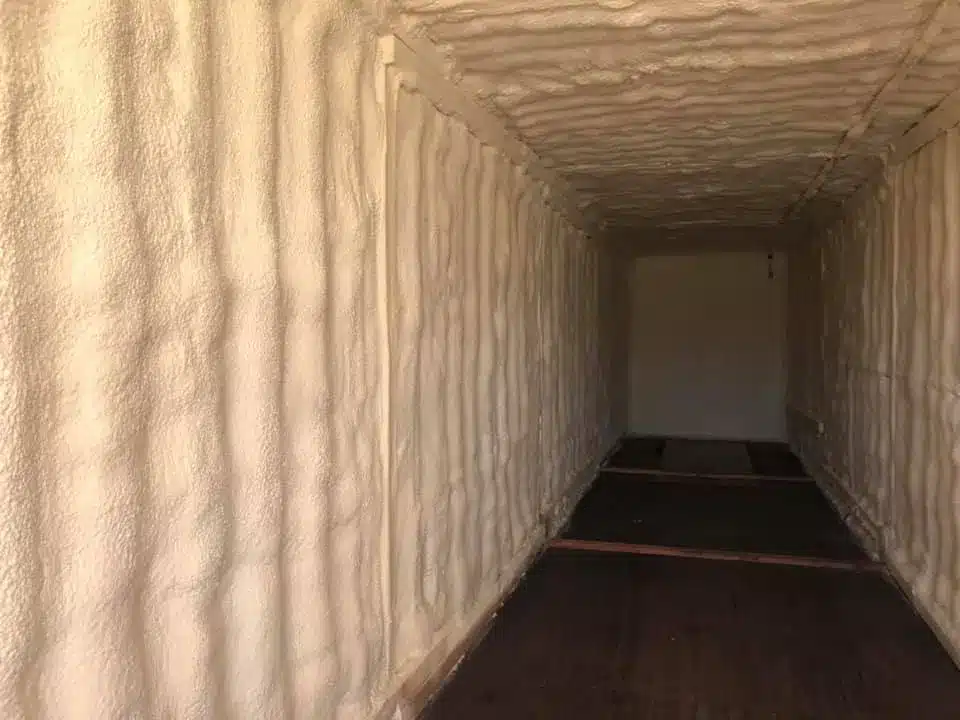

Spray foam insulation creates an airtight seal by expanding into place upon application. While both types do this effectively, their physical structures differ significantly.

Closed-cell foam is dense and rigid. Its cells are completely closed and pressed together, preventing air and moisture from penetrating the material. This density gives it a high insulation value, often around R-6 to R-7 per inch. Because it is so rigid, it can also add structural strength to a building.

Open-cell foam is soft and spongy. Its cells are not completely closed, allowing air to fill the open spaces within the material. This structure gives open-cell foam a lower R-value, typically around R-3.5 to R-3.6 per inch. It remains flexible after curing, which allows it to accommodate building movement without cracking.

Direct Comparison of Specifications

The table below highlights the technical differences that impact performance and application.

| Feature | Closed-Cell Spray Foam | Open-Cell Spray Foam |

|---|---|---|

| R-Value per Inch | R-6.0 to R-7.0 | R-3.5 to R-3.6 |

| Density | 1.75 to 2.0 pounds per cubic foot | 0.4 to 0.5 pounds per cubic foot |

| Vapor Permeability | Impermeable (acts as a vapor barrier) | Permeable (allows moisture vapor) |

| Expansion Rate | Low (30 to 40 times liquid volume) | High (100 to 150 times liquid volume) |

| Air Sealing | Excellent | Excellent |

| Cost | Higher material and installation costs | Lower material and installation costs |

When Closed-Cell Foam is the Better Choice

Closed-cell foam is the superior option when space is limited or moisture control is a priority. Because of its high R-value per inch, a builder can achieve the required thermal performance with a thinner layer of material. This makes it ideal for cathedral ceilings, basements, and crawl spaces where headroom is at a premium.

Moisture resistance is the main advantage of closed-cell foam. In humid climates or areas prone to flooding, such as coastal regions or basements, closed-cell foam prevents water vapor from passing through the insulation. This characteristic helps prevent mold growth and wood rot behind the walls. Data from the U.S. Department of Energy indicates that proper air sealing and moisture control can reduce heating and cooling costs by up to 15% in many homes.

Bonus Tip: Use closed-cell foam on the underside of roof decks in hot climates to create a conditioned attic. This prevents ductwork from baking in the summer and keeps the attic temperature closer to the living space.

When Open-Cell Foam Makes Sense

Open-cell foam is often selected for interior wall cavities and attics in drier climates. Its rapid expansion allows it to fill hard-to-reach nooks and crannies more effectively than closed-cell foam, ensuring a complete seal around wires and pipes. This expansive nature also makes it useful for soundproofing. The open structure absorbs sound waves, reducing noise transmission between rooms or from the outside.

The lower cost of open-cell foam solution is another major factor. It generally costs significantly less per board foot than closed-cell foam. For large projects with a tight budget, open-cell provides excellent air sealing and thermal performance at a fraction of the price of closed-cell systems.

Bonus Tip: Open-cell foam is excellent for sealing attics in dry climates because it traps air but allows the roof deck to “breathe,” reducing the risk of trapped moisture if a minor roof leak occurs.

Regional Climate Considerations

The local climate plays a significant role in this decision. All Foam & Insulation, LLC frequently handles projects in the Pacific Northwest, where winters are wet and humid. In this region, moisture management is just as important as thermal performance. Closed-cell foam is often the preferred choice for exterior walls and crawl spaces in the Rogue Valley area because it stops water vapor from entering the home envelope.

Conversely, in drier, extreme-cold climates, the vapor barrier properties of closed-cell foam help keep warm interior air from escaping and condensing in cold wall cavities. In mixed or dry climates where humidity is less of a concern, open-cell foam offers a cost-effective way to meet high air-sealing standards.

Market Trends and Efficiency Data

The insulation market has seen a shift toward higher-performance materials in recent years. According to a report by the Spray Polyurethane Foam Alliance, spray foam insulation continues to gain market share due to its ability to outperform traditional fiberglass batts in both air sealing and thermal resistance.

Research from the Building Science Corporation confirms that air leakage accounts for a significant portion of energy loss in residential buildings. While both open-cell and closed-cell foams effectively address air leakage, closed-cell foam offers the added benefit of thermal resistance at thinner profiles, which is increasingly important in modern high-performance building designs.

Things to Consider Before Making a Decision

Before committing to a product, evaluate these specific factors:

- Budget Constraints: Determine if the higher initial cost of closed-cell foam fits the budget or if the savings from open-cell foam can be allocated to other efficiency upgrades.

- Space Limitations: Measure the cavity depth. If space is tight, closed-cell foam provides the necessary R-value in a thinner layer.

- Humidity Levels: Assess the moisture risk. Basements, crawl spaces, and coastal homes generally benefit from the vapor barrier properties of closed-cell foam.

- Sound Control: If reducing noise transmission is a priority, open-cell foam is often the better choice due to its sound-absorbing qualities.

- Existing Structure: Retrofit projects might benefit from open-cell foam if the framing has many irregularities, as its high expansion fills gaps more completely.

Frequently Asked Questions

Which type of foam provides the best return on investment?

Return on investment depends on the climate and application. In hot or humid climates with high cooling loads, closed-cell foam often pays for itself more quickly due to its superior thermal resistance and moisture barrier properties. In milder or dry climates, open-cell foam frequently provides a better return because it achieves airtightness at a lower upfront cost.

Can spray foam cause roofing problems?

Improper installation can lead to issues. If an attic is insulated with spray foam directly to the roof deck, the attic becomes a conditioned space. This requires proper ventilation or the correct type of foam to ensure the roof decking stays dry. Closed-cell foam is usually preferred for this application to prevent moisture from reaching the wood sheathing.

How long does spray foam insulation last?

When installed correctly, both types of spray foam are designed to last the lifetime of the building. They do not sag, settle, or degrade like traditional fiberglass or cellulose insulation.

Is one type safer than the other regarding indoor air quality?

Both products are safe once fully cured. The curing process involves off-gassing, which is why occupants must vacate the property during installation and for a short period afterward. Closed-cell foam has a higher chemical density, so proper ventilation during the curing phase is even more critical than with open-cell foam.

Final Thoughts

Choosing between open-cell and closed-cell spray foam requires looking beyond the R-value. Closed-cell foam provides the highest thermal resistance per inch and acts as a vapor barrier, making it ideal for wet climates and tight spaces. Open-cell foam offers superior sound damping and expansion at a lower price point, making it well-suited to dry climates and larger cavities. Homeowners should evaluate their specific moisture risks, budget, and long-term comfort goals to make the right choice.

Get Professional Help

Deciding on the right insulation strategy requires professional assessment. Contact All Foam & Insulation, LLC to discuss specific project needs. For expert advice or a consultation, email [email protected] or call (541) 826-9600 to ensure the investment yields the best possible results.

Sources

- U.S. Department of Energy – Official government resource on insulation types, R-values, and energy savings tips.

- Spray Polyurethane Foam Alliance – Industry trade association providing technical data, market statistics, and safety information regarding spray foam insulation.

- Building Science Corporation – A consulting and research firm providing authoritative information on building physics, moisture control, and energy efficiency.