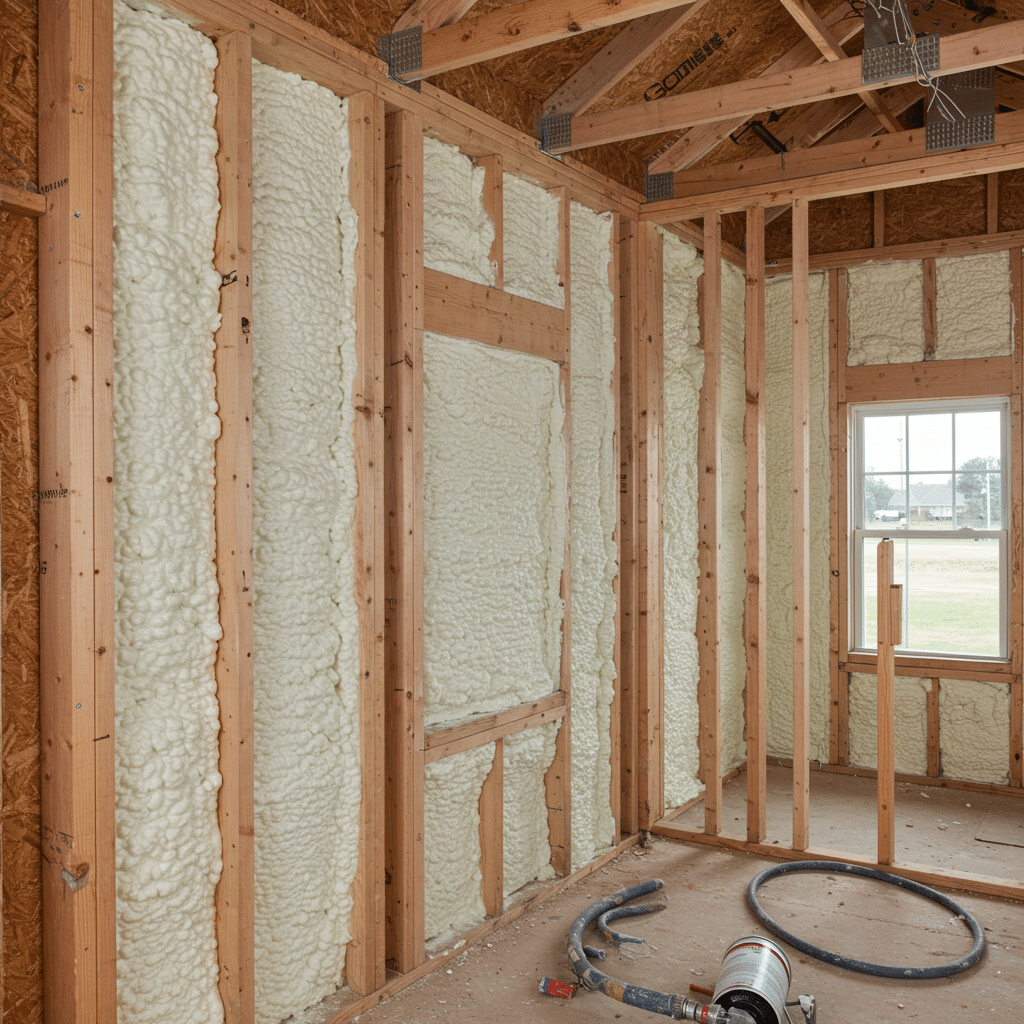

Open-cell spray foam insulation is highly effective for sound damping in Medford properties because it excels at absorbing airborne sound waves. Sound damping aims to reduce noise intensity relying on absorption. Due to its unique low-density and highly porous cellular structure, open-cell foam traps acoustic energy within the wall or ceiling cavity. This action minimizes reverberation and significantly reduces the transmission of everyday domestic noises, such as voices, television, and light activity, directly addressing primary noise complaints in residential and mixed-use buildings.

Property owners aiming for quiet, comfortable interior environments must recognize that thermal insulation and acoustic performance are related but require different material properties. Open-cell foam delivers dual functionality: strong acoustic performance and effective thermal insulation, making it an efficient choice for interior partitions, floor assemblies, and utility spaces. Understanding how this material interacts with sound waves is the key to creating a truly tranquil space.

The Mechanism of Acoustic Absorption

Acoustic energy travels as pressure waves. When a sound wave encounters a material, it may reflect, transmit, or be absorbed. Open-cell foam is lightweight, typically weighing between 0.4 and 1.2 pounds per cubic foot. The critical factor is its cellular structure: the cells are intentionally left open, connected, and air-filled. When a sound wave enters this labyrinthine structure, its energy is forced to change direction repeatedly, and the friction generated converts it into negligible heat.

This conversion process, known as acoustic dissipation, is what defines sound absorption. Unlike dense, rigid materials like closed-cell foam, which tend to reflect sound waves, open-cell foam is designed to let sound penetrate and die out internally. This makes it particularly effective against mid- and high-frequency components commonly associated with human speech and electronic noise.

Comparing Insulation Types for Noise Control

Effective noise mitigation requires selecting the material best suited for the type of noise encountered. While structural noise (footfalls, washing machine vibration) often requires decoupling systems, airborne noise (voices, traffic) is managed effectively by highly absorptive materials. The Noise Reduction Coefficient (NRC) is a standard measure of a material’s ability to absorb sound, and open-cell foam typically provides high ratings.

| Material Type | Typical Density (lb/ft³) | Primary Acoustic Function | Noise Reduction Coefficient (NRC) Range | Best Interior Use Case |

|---|---|---|---|---|

| Open-Cell Foam | 0.4 – 1.2 | Absorption & Air Sealing | 0.40 – 0.65 | Interior walls, ceilings, and utility rooms |

| Closed-Cell Foam | 1.7 – 2.5 | Blocking & Air Sealing | 0.10 – 0.20 | Exterior walls, structural applications |

| Standard Fiberglass Batts | 0.5 – 1.0 | Absorption (Poor Air Seal) | 0.70 – 0.85 (Thick Batts) | Walls where air sealing is not critical |

| Mineral Wool Batts | 2.5 – 4.0 | Absorption & Fire Resistance | 0.90 – 1.00 | High-performance acoustic partitions |

Open-cell foam provides a crucial advantage over traditional batts: superior air sealing. Noise often travels through even tiny gaps and cracks (flanking paths) within the wall assembly. By completely sealing the cavity, open-cell foam eliminates these pathways, enhancing the wall’s overall noise reduction far beyond what the NRC rating alone suggests.

Regional Considerations for Noise and Climate

Medford properties, like many in the Rogue Valley, must contend with a combination of climate demands and urban noise issues, particularly near commercial areas or busier roadways. Because the region experiences both high summer heat and cold winters, thermal performance is essential in interior spaces as well. Open-cell foam in Medford, OR, typically offering an R-value of R-3.5 to R-3.8 per inch, provides the thermal separation needed for interior walls while prioritizing critical acoustic control.

Airborne noise is particularly challenging in the mid-range frequencies, which include most conversation and household sounds. A review published by Taylor & Francis Online confirmed that lightweight, porous polyurethane foams offer performance benefits over denser insulation types, particularly in reducing mid-range frequency transmission loss in wall structures. This makes the selection of open-cell foam strategically sound for mitigating typical domestic noise issues.

Things to Consider Before Making a Decision

Before undertaking any sound-dampening project, property owners must clearly define the specific acoustic goals of the treatment. Installing open-cell foam is a permanent, high-performance solution, making careful planning necessary.

Identify the Noise Source and Frequency

Property owners should first determine the nature of the disturbance: is the problem primarily airborne (voices, TV) or structure-borne (foot traffic, plumbing vibrations)? While open-cell foam excels at airborne noise absorption, structural noise requires additional measures, such as decoupling channels or mass-loaded vinyl, to isolate vibrations from the building’s framing.

Required Level of Air Sealing

Open-cell foam acts as an effective air barrier, stopping drafts and preventing noise transfer through gaps. Ensure the material will be applied completely to maximize air-sealing benefits, which significantly boost acoustic performance. This thorough coverage is key to success.

Understand Acoustic Goals

If the goal is moderate sound dampening for everyday comfort, open-cell foam alone often suffices. However, for residential dampening projects, maximizing the thickness of the open-cell foam layer is usually more beneficial than focusing solely on R-value, as a full cavity fill provides the maximum surface area for sound wave friction and energy dissipation. If the goal is professional sound isolation (e.g., a recording studio or commercial facility), the foam must be integrated into a larger assembly that includes high-mass layers (e.g., specific drywall types) and potentially staggered stud framing to achieve the highest Sound Transmission Class (STC) ratings.

Why Porosity Outweighs Density for Absorption

It is inaccurate to assume that denser materials are always better for sound control. While density improves sound blocking (often needed to reduce external traffic noise), absorption relies on porosity and airflow resistance. According to findings highlighted by the Acoustical Society of America, effective acoustic materials must allow air to flow slightly through their structure to create the internal resistance necessary to convert sound energy into heat. Open-cell foam provides this optimal flow resistance.

For interior applications focused on quiet spaces, the spongy, air-filled nature of open-cell foam is precisely what is required. Materials that are too dense or completely rigid, like closed-cell foam, will simply reflect much of the sound wave into the space, offering minimal absorption unless they are structurally decoupled.

Open-Cell Foam in Existing Property Upgrades

Many Medford properties require sound dampening after construction is complete. While installing open-cell foam requires accessing the wall cavity, usually involving the removal of existing drywall or the drilling of injection holes, the long-term acoustic payoff often justifies the effort. Once installed, the foam permanently fills all voids, eliminating hidden noise paths that conventional batts cannot address.

The application process must be handled precisely to ensure uniform density and full cavity coverage. Data reviewed by Spray Foam Magazine suggests that proper installation of open-cell foam in standard stud walls often results in a noticeable STC improvement, resulting in quieter spaces where airborne noise is substantially attenuated.

Summary of Key Benefits

Selecting open-cell foam for sound dampening is a targeted strategy that prioritizes acoustic absorption and air sealing. The material’s porosity helps mitigate common mid- to high-frequency airborne noise, which can reduce comfort in residential and commercial settings. Property owners achieve genuine peace by ensuring the entire wall cavity is filled, minimizing internal noise transmission, and securing long-term thermal separation. Evaluate noise sources carefully and ensure the material selection aligns precisely with the acoustic goals.

Contacting Insulation Experts

Choosing the correct spray foam application for specialized sound dampening requires expertise in both building science and acoustic treatment. All Foam & Insulation, LLC provides professional guidance on material selection and application strategies, ensuring the chosen solution effectively addresses specific noise issues, whether thermal, structural, or acoustic. Discuss project needs or acoustic challenges by calling (541) 826-9600, or by reaching out to [email protected]. Expertise ensures maximum sound absorption benefits are realized.

Sources

- Taylor & Francis Online – Academic research discussing the acoustic properties and mid-range frequency performance benefits of polyurethane foam in reducing sound transmission loss.

- Acoustical Society of America – Technical paper explaining the relationship between air flow resistance, porosity, and sound absorption in porous materials.

- Spray Foam Magazine – Industry resource providing context and typical data regarding the noise reduction capabilities and STC improvements achieved by using spray foam.

FAQS

How effective is this foam against heavy street traffic noise?

For heavy, low-frequency traffic noise, open-cell foam alone is generally insufficient. Traffic noise requires high mass to reflect the long, powerful sound waves. Open-cell foam should be used in conjunction with mass-loaded layers (such as heavy drywall) to maximize the Sound Transmission Class (STC) rating of the exterior wall assembly.

Does the foam’s R-value affect its sound-absorption performance?

The R-value (thermal resistance) and acoustic absorption are largely independent metrics. Open-cell foam has a lower R-value per inch than closed-cell foam, but its acoustic performance is higher precisely because of its lower density and higher porosity. For sound dampening, prioritize the material’s NRC rating and its ability to seal air gaps, not just its thermal R-value.

Is open-cell foam resistant to pests like rodents?

Rodents and pests do not use open-cell foam as a food source. However, rodents may chew through any insulation material if they are determined to pass through an area. The foam’s rigid, monolithic nature and ability to seal all gaps make it significantly harder for pests to nest or infiltrate than loose-fill insulation or batts.

What preparation is needed before applying sound-dampening foam?

The wall cavity must be clean, dry, and free of dust or debris. Electrical wiring and plumbing must be correctly routed and secured within the cavity before application. If the wall is exterior, a continuous vapor retarder may be required, depending on local building codes and the presence of interior or exterior sheathing.