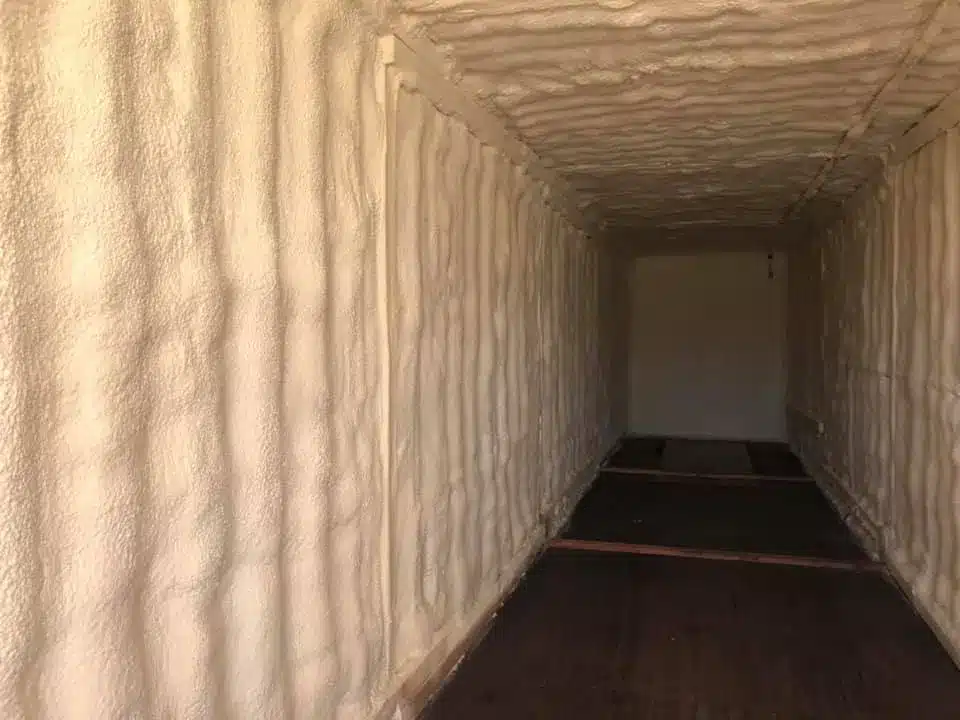

Investing in quality open-cell insulation yields substantial, long-term returns primarily through immediate energy savings, superior air sealing, and improved interior comfort. Unlike traditional insulation materials that merely slow down heat transfer, open-cell foam expands to fill every cavity, crack, and void, creating a comprehensive air barrier. This tight seal stops conditioned air from escaping and unconditioned air from entering, directly reducing the workload on heating and cooling systems and leading to predictable reductions in monthly utility bills over the life of the structure. High-quality application ensures these benefits remain constant for decades, providing a reliable defense against fluctuating energy costs.

Open-cell insulation is a lightweight, practical product ideal for residential and light commercial structures, especially in wall cavities and attic applications. Understanding its long-term performance requires looking past the initial cost and focusing on the total operational savings and increased structural integrity it provides.

Maximizing Energy Efficiency and Cost Reduction

While insulation R-value is often the primary metric for efficiency, the ability to stop air movement is arguably more critical for achieving actual thermal performance. Open-cell spray foam insulation excels here because of its low density and flexible structure. Once applied, the foam expands rapidly, conforming perfectly to irregular shapes, electrical runs, and plumbing protrusions. This action seals the building envelope tightly, preventing uncontrolled air leakage, which, according to the US Department of Energy, often accounts for 25% to 40% of the energy used for heating and cooling in homes.

When a home or commercial building is sealed this effectively, the existing HVAC system often operates more efficiently, sometimes allowing for the use of smaller, less expensive equipment during initial construction or replacement. The reduction in thermal bridging, a common issue where structural materials like wood studs conduct heat through the insulation layer, further locks in savings.

Bonus Tip: Sizing Systems Correctly. When installing high-performance insulation, recalculate the necessary capacity of the heating and cooling equipment. Over-sizing HVAC units is standard, but a properly sealed building requires less capacity, saving money on equipment purchases and reducing energy cycles.

Sound Dampening and Improved Indoor Environment

Open-cell foam provides a significant benefit often overlooked: noise reduction. The soft, porous nature of the cured foam makes it an excellent sound-absorbing material. The open-cell structure traps airborne sound waves within its matrix, dramatically lessening the transmission of external noise (traffic, airplanes, neighbors) and internal noise (plumbing runs, media rooms) through walls and floor cavities. This capability is especially valuable in dense urban environments or structures with shared walls.

Furthermore, by sealing every intrusion point, open-cell foam helps manage moisture movement and airborne pollutants. A controlled environment reduces the likelihood of mold or mildew growth related to condensation and limits the entry of dust, allergens, and pests. This directly contributes to healthier, better-controlled indoor air quality.

Comparison of Common Insulation Types

Choosing the proper insulation requires balancing R-value, air-sealing capabilities, and material cost. The table below compares open-cell foam to traditional insulation options based on key performance indicators.

| Feature | Open-Cell Spray Foam | Fiberglass Batts | Cellulose (Blown-In) |

|---|---|---|---|

| Primary R-Value (per inch) | R-3.5 to R-3.9 | R-2.9 to R-3.8 | R-3.2 to R-3.8 |

| Air Sealing Capability | Excellent (Air Barrier) | Poor | Fair (Requires dense packing) |

| Sound Dampening | High | Low | Moderate |

| Moisture Permeance | High (Vapor Permeable) | Moderate | Moderate |

| Application Method | Spray Applied, Expands | Friction Fit/Stapled | Blown-In |

Durability, Lifespan, and Climate Performance

Quality open-cell insulation is designed to last the life of the structure. Unlike fiberglass or cellulose, which can settle, sag, or degrade over time, properly installed spray foam remains dimensionally stable. It adheres permanently to the substrate, meaning its performance does not diminish under normal conditions. This longevity secures the initial investment by providing a steady return through consistent energy savings, eliminating the need for periodic replacement or maintenance typical of some fibrous materials.

In regions that experience significant temperature swings, such as the upper Midwest and the Mountain West, open-cell foam provides the necessary resilience. While open-cell foam absorbs water if directly exposed, its porous nature is key because it allows trapped moisture to drain or dry out quickly. This characteristic is often acceptable and sometimes preferred for specific attic assemblies in northern climates, where ventilation and vapor permeability are essential for building envelope health, as discussed by experts at Building Science Corporation.

Bonus Tip: Vapor Considerations. Always check local building codes regarding vapor barriers. Because open-cell foam is vapor-permeable, specific assemblies (such as cold-climate exterior walls) may require a separate vapor retarder installed toward the conditioned side of the wall assembly to manage moisture effectively.

Pre-Installation Things to Consider Before Making a Decision

Before finalizing the decision to use open-cell foam, several practical factors must be assessed. These decisions ensure the insulation chosen matches the project’s specific needs and limitations.

- Location and Accessibility: Confirm that the application area is fully accessible for proper installation. Open-cell is ideal for hard-to-reach areas like cathedral ceilings, crawl spaces, and tightly framed wall cavities because of its liquid application and expansion properties.

- R-Value Requirements: While open-cell foam offers excellent air sealing, its R-value per inch is lower than that of closed-cell foam. If space is severely limited (e.g., in a 2×4 wall cavity in a freezing zone), evaluate whether the required total R-value can be met, or if a hybrid approach is necessary.

- Budget and Project Scope: Open-cell foam typically carries a higher installation cost than batt insulation. Always compare this initial expense against the total cost of ownership over 10 or 20 years, factoring in long-term energy savings and comfort improvements.

- Off-Gassing and Curing: Quality foam requires professional installation and proper ventilation during and immediately after application. Ensure the installer adheres to manufacturer guidelines regarding cure time before the area is reoccupied.

Call to Action written:

Investing in quality open-cell insulation transforms your property into a highly efficient, quiet, and comfortable environment by eliminating air leakage and significantly reducing monthly energy costs. To ensure you achieve these lasting benefits and a superior return on investment, trust the experienced team at All Foam & Insulation, LLC. We are ready to analyze your specific building requirements and deliver a solution that lasts the life of your structure. Don’t settle for high utility bills or poor indoor air quality. Take the next step toward a better-performing building today by calling us at (541) 826-9600 or emailing [email protected] to schedule your professional consultation.

Making a Calculated Decision

Quality open-cell insulation delivers tangible value beyond simple R-value ratings by providing comprehensive air sealing, superior sound dampening, and long-term durability. The combination of reduced air exchange and stable thermal resistance results in predictable energy performance and enhanced interior environments. Property owners must evaluate project specifics, regional climate demands, and performance goals to ensure the chosen material maximizes efficiency and long-term satisfaction.

Connecting with Experts

Consulting a qualified professional requires careful consideration of structural needs and specific climate challenges. A certified insulation expert can help property owners analyze their project specifications to choose the best option for maximum performance. If you have technical questions or need an expert evaluation of your building envelope needs, consult a certified local contractor for direct assistance. Taking the time to consult with seasoned professionals ensures the insulation decision aligns perfectly with energy-saving goals and longevity requirements.

Sources

- US Department of Energy – Provides data on energy loss from air leakage in typical homes, supporting claims about insulation’s impact on heating and cooling needs.

- Building Science Corporation – Offers detailed building science insights into the application and performance of insulation materials in various climate conditions, particularly concerning moisture control in attics.

- Spray Foam Magazine – An industry resource that covers installation best practices and reports on research regarding the safety and low emissions of properly cured spray polyurethane foam products.

FAQS

Can open-cell insulation be used below grade or in flood-prone areas?

Open-cell insulation is typically not recommended for applications below grade or in areas subject to standing water. Because it is highly permeable, it can absorb water, which compromises its thermal performance. Closed-cell foam is the superior choice for foundations or areas with potential soil moisture intrusion.

What is the typical return on investment period for spray foam insulation?

The return on investment varies significantly based on climate, existing insulation levels, and energy costs. However, due to substantial energy savings (often 30% or more compared to conventional insulation), many building owners see the investment pay for itself within five to seven years through utility savings alone.

Does open-cell foam provide structural reinforcement?

Open-cell foam provides negligible structural support. While it adheres firmly to surfaces, it is soft and flexible. If structural reinforcement is a goal, the high density and rigidity of closed-cell foam should be considered instead.

How does open-cell insulation handle electrical wiring?

Open-cell spray foam effortlessly encapsulates electrical wiring and junction boxes without issue. Modern spray foams carry fire ratings that meet building code requirements. The foam acts as a thermal barrier but does not generally cause overheating of electrical conductors under normal conditions.

Do spray foam products produce harmful emissions after installation?

According to information reviewed by Spray Foam Magazine, the National Association of Home Builders Research Center confirmed that spray polyurethane foam products exhibit low emissions shortly after installation and cure without issue when appropriately installed.