Spray foam insulation earns its reputation for reliability in extreme weather from three core properties: its ability to create a monolithic, airtight seal, its high resistance to moisture, and its capacity to add structural strength to a building. Unlike traditional insulation solutions that are placed or blown into cavities, spray polyurethane foam (SPF) expands to fill every gap and crack. This process creates a continuous barrier that stops air and water from penetrating the building envelope. This single, comprehensive layer is what stands up so effectively against high winds, driving rain, and drastic temperature shifts.

This article will explain the specific characteristics of spray foam that contribute to its durability during severe weather events. The information is based on years of hands-on experience and industry knowledge in building science and insulation performance. Understanding these details can help property owners make informed decisions about protecting their investments from the elements.

The Science Behind Spray Foam’s Durability

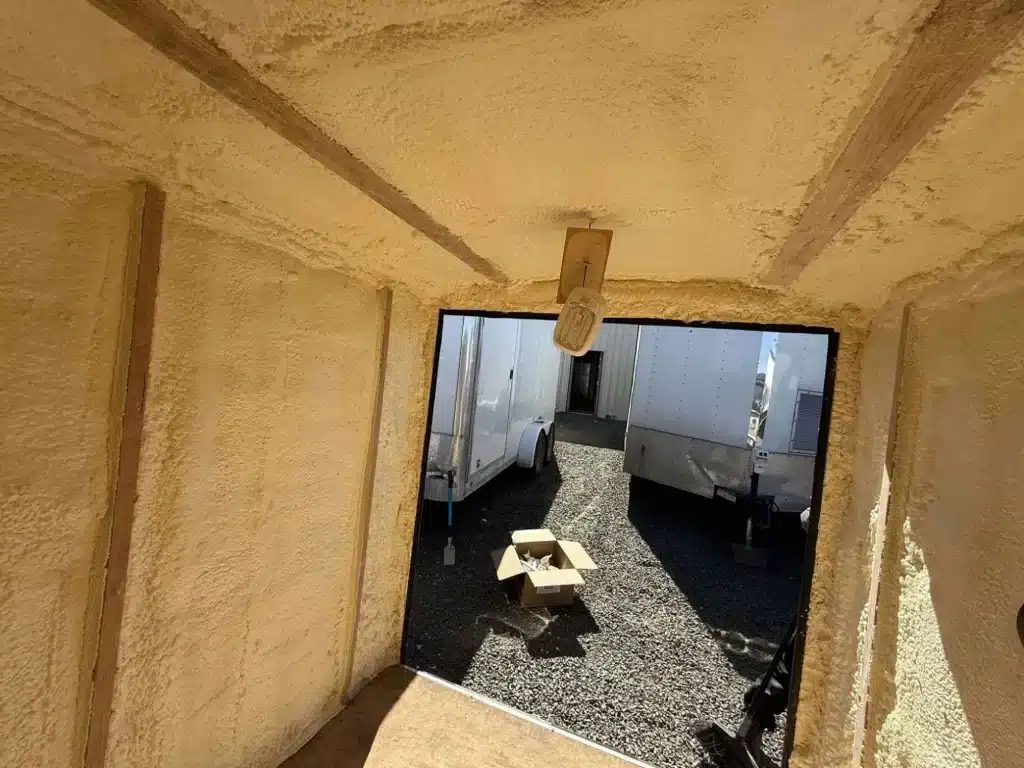

Spray foam insulation begins as two separate liquid components that are mixed at the application site. The resulting chemical reaction causes the material to expand rapidly, adhering tightly to wood, steel, and concrete. This aggressive bonding is what makes it so effective. Instead of just sitting in a wall cavity, it becomes part of the wall itself.

There are two main types of spray foam, and their differences are important for weather resilience:

- Closed-Cell SPF: This type has a dense structure of tiny, closed cells filled with an insulating gas. It is rigid, provides a high R-value (a measure of thermal resistance), and acts as a powerful barrier against both air and water vapor. A publication from the U.S. Department of Energy notes its effectiveness as an air barrier material. Because of its rigidity and low permeability, closed-cell foam is the superior choice for homes in areas prone to high winds, heavy rain, or flooding.

- Open-Cell SPF: This foam is lighter and more flexible, with an open cell structure. While it’s an excellent air barrier and sound insulator, it is vapor-permeable and can absorb water if exposed to bulk moisture. It doesn’t offer the same structural reinforcement or water resistance as its closed-cell counterpart.

Bonus Tip: In regions with heavy snowfall, the structural support from closed-cell spray foam applied to the underside of the roof deck can help the roof bear the weight of accumulated snow and ice.

Performance Against Specific Weather Events

The true test of an insulation material is how it performs when conditions are at their worst. Here’s how spray foam holds up against specific weather threats.

High Winds and Storms

During hurricanes or severe windstorms, buildings are subjected to immense pressure. Wind can force its way through tiny openings, creating a pressure differential that can lift roof sheathing or even push walls outward. Because closed-cell spray foam adheres to the roof deck and wall sheathing directly to the framing, it essentially glues the building’s shell together. Research conducted by the Insurance Institute for Business & Home Safety (IBHS) has demonstrated that homes with sealed roof decks, often achieved with spray foam, show significantly better performance during high-wind events. This added bond can increase a wall’s racking strength and a roof’s resistance to being lifted off the structure.

Heavy Rain and Flooding

Water intrusion is a major concern during storms. For homes in flood-prone areas, insulation that absorbs water, like fiberglass or cellulose, can become a source of mold and decay. Closed-cell spray foam, however, is recognized by FEMA as a flood-resistant material. It has a very low water absorption rate. If a building floods, the insulation will not act like a sponge. Once the floodwaters recede, the walls can be opened, cleaned, and dried, and the closed-cell foam within will remain intact and effective.

Extreme Heat and Cold

The primary job of any insulation is to resist heat flow. Spray foam’s high R-value, combined with its air-sealing capability, makes it extremely effective at this. During a heatwave, it prevents hot, humid outdoor air from infiltrating the building, reducing the load on air conditioning systems. In a cold snap, it stops cold air from getting in and expensive heated air from getting out. This thermal consistency not only improves comfort but also makes the building more resilient during power outages, as it will maintain its interior temperature for a longer period.

Bonus Tip: Sealing the rim joist area in a basement or crawl space with spray foam is one of the most effective ways to stop air leakage, which can account for a significant portion of a home’s energy loss.

Insulation Performance in Extreme Conditions

The following table offers a direct comparison of how closed-cell spray foam performs against traditional insulation materials in key areas:

| Feature | Closed-Cell Spray Foam | Fiberglass Batts | Blown-In Cellulose |

|---|---|---|---|

| Air Sealing | Excellent, forms a complete air barrier. | Poor, allows air to move through and around it. | Fair, settles over time creating gaps. |

| Moisture Resistance | Excellent, resists bulk water and acts as a vapor barrier. | Poor, absorbs water and loses R-value when wet. | Poor, absorbs and holds moisture, can promote mold. |

| Structural Support | Good, adds significant racking strength to walls and roofs. | None. | None. |

| R-Value Retention | Excellent, does not degrade when exposed to moisture. | Poor, R-value drops dramatically when wet. | Poor, R-value is compromised by moisture. |

Things to Consider Before Making a Decision

Choosing the right insulation requires looking at your specific situation. Before deciding, consider these factors:

- Your Local Climate: For those in coastal or storm-prone regions like the Gulf Coast or the Atlantic seaboard, closed-cell spray foam’s wind and water resistance is a major advantage. In colder, northern climates, its ability to prevent ice dams and handle heavy snow loads is a key benefit.

- Building Code Requirements: Local building codes, especially in hurricane zones, may have specific requirements for insulation and roof deck sealing. Always check what is mandated in your area.

- Ventilation Needs: Creating an airtight building envelope with spray foam means you must have a plan for mechanical ventilation. A balanced system like an Energy Recovery Ventilator (ERV) or Heat Recovery Ventilator (HRV) is often necessary to ensure healthy indoor air quality.

- Professional Installation: The performance of spray foam is entirely dependent on the quality of the installation. The chemicals must be mixed at the correct temperature and ratio. Always work with a certified and experienced installer.

Frequently Asked Questions

Does spray foam lose effectiveness over time?

Properly installed spray foam does not sag, settle, or shrink over time. Its thermal and air-sealing properties should last for the life of the building.

Is spray foam fire-resistant?

Spray foam is a combustible material, like wood. However, building codes require it to be covered by a 15-minute thermal barrier, such as half-inch drywall or a special intumescent coating, which provides sufficient fire protection.

How does spray foam handle freeze-thaw cycles?

Closed-cell spray foam performs very well in climates with frequent freeze-thaw cycles. Because it prevents moisture from getting into the building assembly, it helps stop the damaging effects of water freezing and expanding within cracks and materials.

Can spray foam help prevent ice dams in snowy climates?

Yes. Ice dams form when heat escapes from the living space into the attic, melting snow on the roof. The water then runs down and refreezes at the colder eaves. By applying spray foam directly to the underside of the roof deck, you create an unvented or “hot roof” assembly. This stops heat from reaching the roof deck in the first place, keeping it cold and preventing the snow from melting.

Is closed-cell spray foam approved for use in hurricane-prone regions?

Yes, it is often a preferred material. Its ability to bond the roof deck to the trusses or rafters makes the entire roof assembly more resistant to wind uplift, which is a primary cause of roof failure during a hurricane.

What is the expected lifespan of spray foam insulation?

When installed correctly and not exposed to direct sunlight (which can degrade it), spray foam insulation is expected to last for the life of the building, which could be 80 years or more.

Does spray foam off-gas, and is it safe after curing?

During the application process, spray foam releases chemical vapors, which is why professional installers wear full protective gear and ventilate the area. However, once the foam has fully cured, typically within 24 hours, it becomes an inert plastic and is considered safe.

Final Thoughts

The reliability of spray foam in extreme weather isn’t due to a single feature but the combination of its air-sealing, moisture-blocking, and structural-enhancing properties. It creates a unified, resilient building shell that is simply more durable than one built with traditional, permeable insulation. When evaluating how to protect your property, consider the long-term performance and protection offered by the materials you choose. Assessing your home’s specific vulnerabilities and your region’s weather patterns will help you determine the best approach for long-term safety and efficiency.

Learn how our expanded spray foam insulation services are improving energy efficiency and weather resistance in more areas through our latest service update.

Get a Professional Assessment

Understanding how these materials apply to your specific structure is key. For a detailed evaluation and clear answers tailored to your property, contact the team at All Foam & Insulation, LLC. You can reach an expert by calling (541) 826-9600 or sending an email to [email protected] to discuss your project’s needs.

Sources

- U.S. Department of Energy – Provides an overview of spray foam insulation types and their properties as air barriers.

- Insurance Institute for Business & Home Safety (IBHS) – Offers research and standards for building stronger, more resilient homes, including information on sealed roof decks.

- FEMA – This technical bulletin from the Federal Emergency Management Agency lists closed-cell spray foam as a flood-damage-resistant insulation material.